Industrial Utility Application

Sigma Flow

Industrial Utility Application

Industries are major global water consumers, using 70-80% of the total water supply. Efficient water distribution and treatment are critical for sectors like power generation, steelmaking, mining, and paper production. Valves are essential for controlling the flow in applications such as cooling water, fire systems, wastewater treatment, and drinking water supply. Industrial colonies also rely on valves for their own water treatment plants and backup water systems, ensuring smooth operations across various processes.

Topographic Complexity

The varied landscape affects water flow.

Network Connectivity

The intricate connections between different systems.

Regulatory Systems

Different functional regulatory frameworks complicate management.

Demand Variability

Fluctuations in water demand over time and space.

Pipeline Friction

The interaction between water and pipeline surfaces.

Non-Revenue Water

High percentages of water that do not generate revenue.

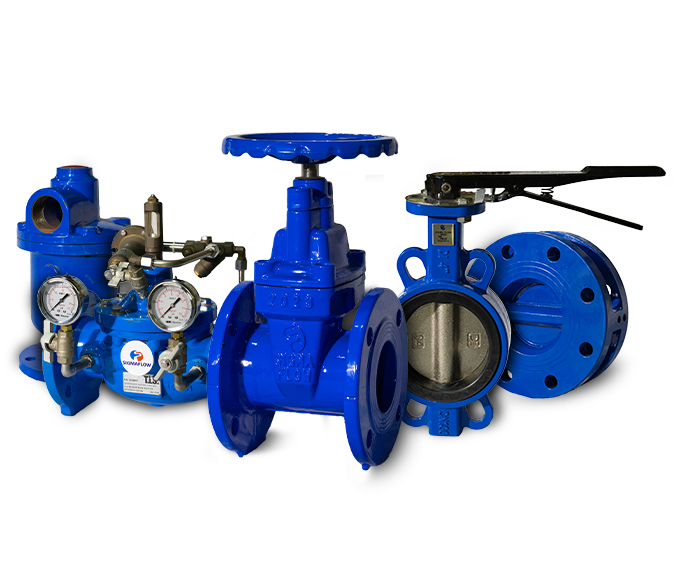

At Sigma Flow, we specialize in providing reliable isolation valves, including gate valves and butterfly valves, designed to minimize service disruptions during maintenance and repair. These valves are strategically placed to ensure that sections of the network can be isolated with minimal inconvenience to other service areas.

Services

Tailor made digital products and creative solutions for businesses.

Through a deep understanding of our audience’s makeup and motivations, we design digital experiences that connect with people.

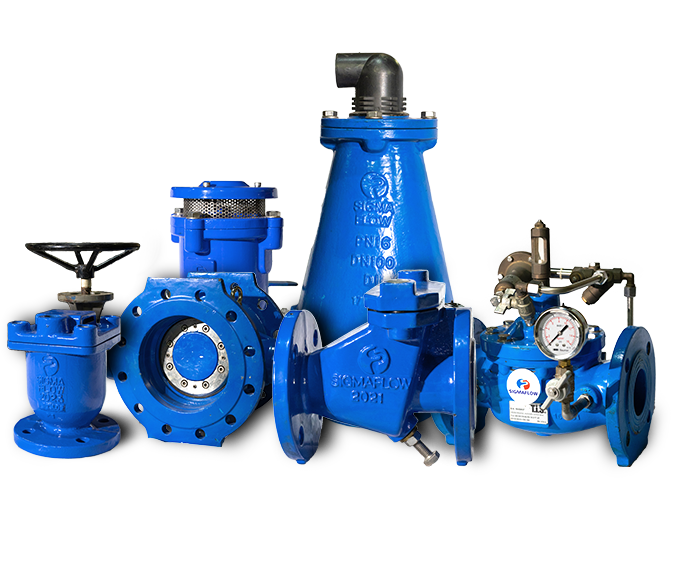

Air Valves

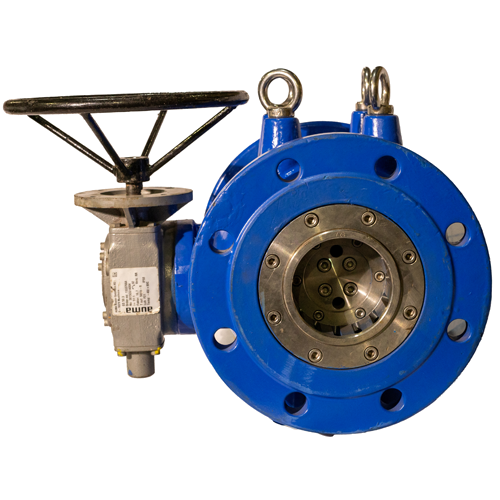

Butterfly Valves

Gate Valves

Non-Return Valves

Control Valves

Control valves are integral to managing flow and pressure within the distribution system.

They are sized based on the desired flow rates, upstream and downstream pressure differentials, and flow velocities. SIGMAFLOW offers a variety of control valves, including pressure-reducing, pressure-sustaining, pressure-relief, flow-control, throttling, and float valves.

For maintaining optimal flow

Additionally, air release valves, essential for maintaining optimal flow, are installed at high points or gradient changes in the main pipeline. SIGMAFLOW provides a comprehensive range of air valves specifically designed for distribution lines.

Key Benefits of Valves in Industrial Systems

Valves are essential components in industrial systems, contributing to overall system efficiency and safety. They play a key role in enhancing reliability, reducing downtime, and ensuring the longevity of equipment and processes.

- 1.Flow Regulation: Gate and butterfly valves regulate flow precisely, with gate valves providing full shutoff and butterfly valves offering compact control.

- 2. Pressure Control: Check valves prevent backflow, while knife gate valves handle high-pressure and slurry applications effectively.

- 3. Space & Budget Efficiency: Butterfly valves save space and cost, and gate valves offer reliable operation in larger systems.

- 4. Operational Safety: Check valves prevent reverse flow, and knife gate valves ensure secure shutoff in critical systems.

- 5. Maintenance Reduction: Gate, butterfly, and knife gate valves reduce maintenance with durable materials, while check valves protect against backflow damage.

Boost Efficiency with Our Valve Solutions

Boost your industrial operations with our advanced valve solutions, tailored for utility applications. Our valves are engineered to regulate flow, control pressure, and enhance safety, ensuring smooth and efficient system performance. With robust durability, minimal maintenance, and cost-effective design, they improve reliability and reduce downtime. Count on our valves for optimized performance across industries like power, steel, and water treatment. Achieve optimal efficiency and safety—select our valves for all your industrial requirements.