Booster Pumping

Sigma Flow

Booster Pumping

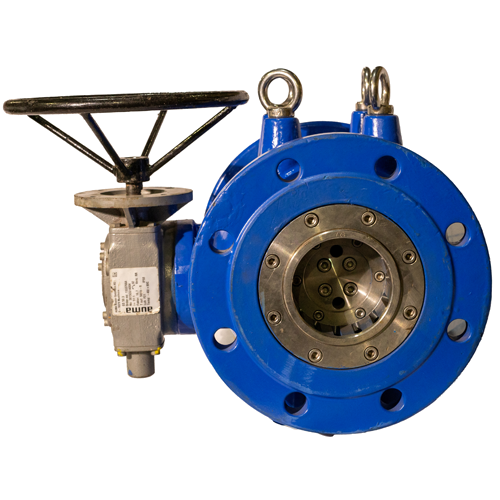

Valves in pumping / booster pumping stations play an important and vital role in protecting high-cost and operational equipment, including pumps, prime movers, control & measurement systems etc. Failure of valves will not only lead to a process shutdown but also could potentially result in the destruction of vital infrastructure. As differential pressure is inherent to the pumping station process, noise, vibration and cavitation will be persistent challenges that need to be overcome.

Topographic Complexity

The varied landscape affects water flow.

Network Connectivity

The intricate connections between different systems.

Regulatory Systems

Different functional regulatory frameworks complicate management.

Demand Variability

Fluctuations in water demand over time and space.

Pipeline Friction

The interaction between water and pipeline surfaces.

Non-Revenue Water

High percentages of water that do not generate revenue.

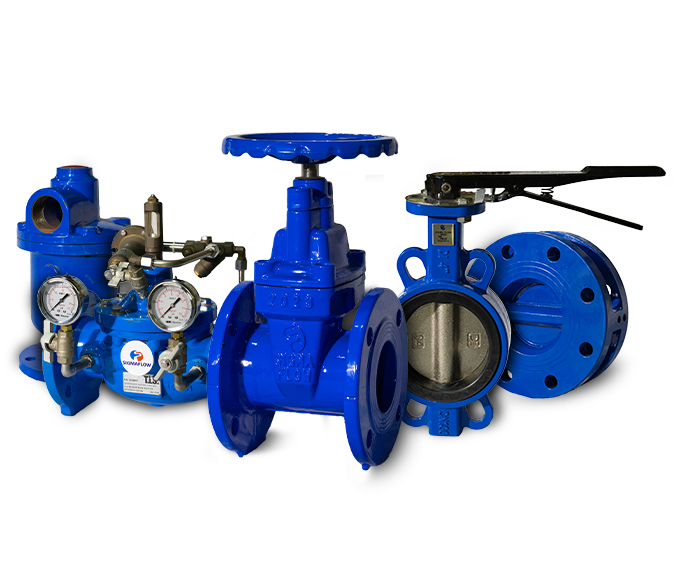

At Sigma Flow, we specialize in providing reliable isolation valves, including gate valves and butterfly valves, designed to minimize service disruptions during maintenance and repair. These valves are strategically placed to ensure that sections of the network can be isolated with minimal inconvenience to other service areas.

Services

Tailor made digital products and creative solutions for businesses.

Through a deep understanding of our audience’s makeup and motivations, we design digital experiences that connect with people.

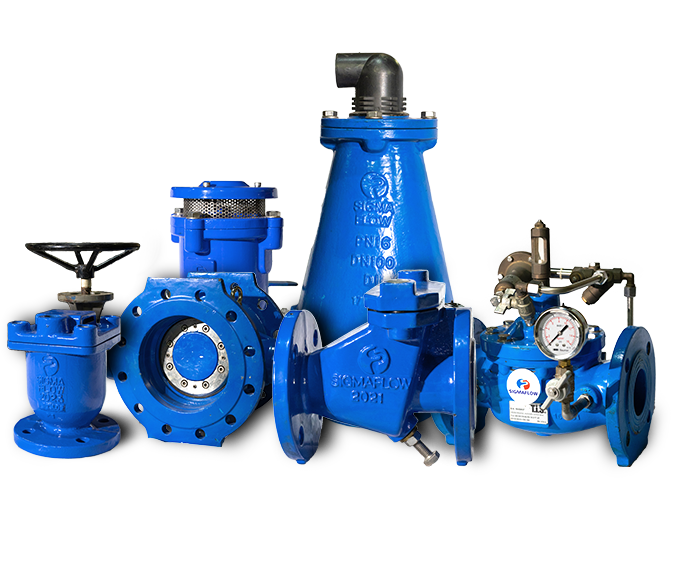

Air Valves

Butterfly Valves

Gate Valves

Non-Return Valves

Control Valves

Control valves are integral to managing flow and pressure within the distribution system.

They are sized based on the desired flow rates, upstream and downstream pressure differentials, and flow velocities. SIGMAFLOW offers a variety of control valves, including pressure-reducing, pressure-sustaining, pressure-relief, flow-control, throttling, and float valves.

For maintaining optimal flow

Additionally, air release valves, essential for maintaining optimal flow, are installed at high points or gradient changes in the main pipeline. SIGMAFLOW provides a comprehensive range of air valves specifically designed for distribution lines.

Advantages of Integrating Sigma Valves

in Booster Pumping Systems

Valves play a crucial role in booster pumping systems by ensuring efficient flow control, pressure regulation, and system protection. They enhance performance, reduce energy consumption, and improve the overall reliability of operations.

- 1. Pressure Regulation: Valves maintain consistent pressure in booster pumping systems, ensuring efficient water distribution and preventing overpressurization.

- 2. Flow Control: They enable precise control of water flow, allowing operators to meet varying demand requirements without wasting energy or resources.

- 3. System Protection: Valves safeguard pumps and pipelines from damage caused by water hammer, backflow, or sudden pressure surges.

- 4. Energy Efficieny: By optimizing flow and reducing unnecessary strain on pumps, valves contribute to lower energy consumption and operating costs.

- 5. Enhanced Reliability: Properly installed valves improve the durability and performance of booster pumping systems, minimizing downtime and maintenance needs.

Optimizing Raw Water Usage

Unlock the potential of your water systems with our innovative raw water solutions. Designed for efficiency and durability, our products optimize performance, reduce costs, and simplify the management of untreated water. Whether for industrial cooling or agricultural irrigation, our technology ensures sustainable, reliable usage. Protect infrastructure, minimize downtime, and maximize productivity with our tailored solutions, delivering long-term value and efficiency for your operations.